METCAL CV-IOT Gateway Newly Launched CV-5200 Series Welding Platform Partner

Utilize connection verification ® The powerful features of the system and the new Metcal CV-IOT gateway allow manufacturers to apply more welding data than ever before.

● Determine which soldering iron tips are being used on each soldering station;

● Track the welding process by automatically evaluating each welding point to ensure that the process meets the process standards;

● Understand productivity troughs and peaks;

●Set up alerts for ESD events.

Check the welding statistics data when the circuit board malfunctions;

● By analyzing unprecedented data mining, we can quickly identify the root cause of welding point failures;

● By analyzing the important indicators of the relevant processes, exploration can be conducted at the circuit board level.

About CV-IOT

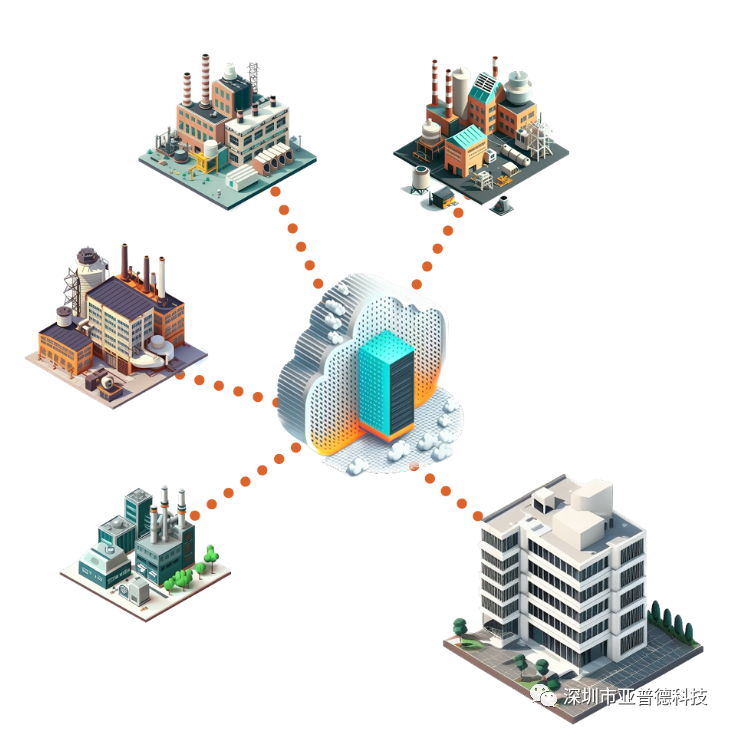

Track each welding point.

Not only locally, but also from every site on the network.

Collect data for each solder joint on each soldering station, including the type of soldering iron used, soldering iron temperature, soldering time, solder joint quality evaluation, etc.

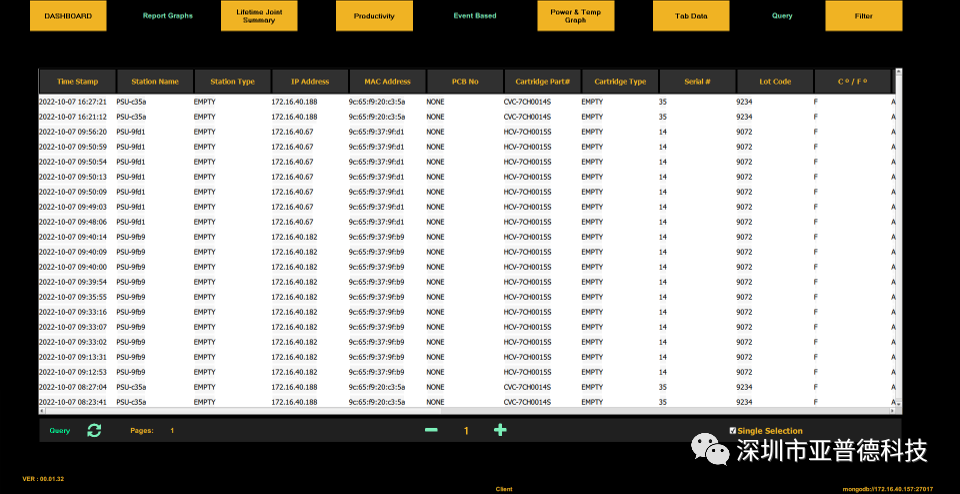

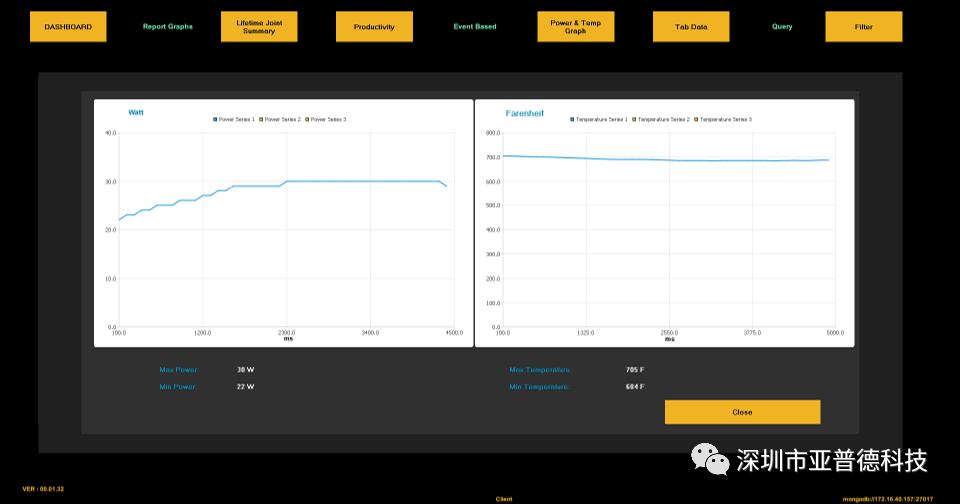

By using an intuitive main page and easily configurable software to analyze data, productivity and system status can be easily viewed with a clear eye. Optimize data views through filters and user configurations.

View data in graphical or database format - easily export data in CSV format for your own analysis. The information for each welding event is stored using a standard database structure. Ensure data compatibility with standard database applications.

Add barcode information to your data package using a barcode scanner (not included in the supply scope).

Browse CV-IOT gateway software

The CV IoT main page displays (top left) welding events over a period of time, (top right) soldering iron tip lifespan, and (bottom left) production workshop status updates

And (bottom right) the productivity between each welding station.

Analyze the original information as a database on the screen, or export CSV format files for further analysis, reporting, and record keeping.

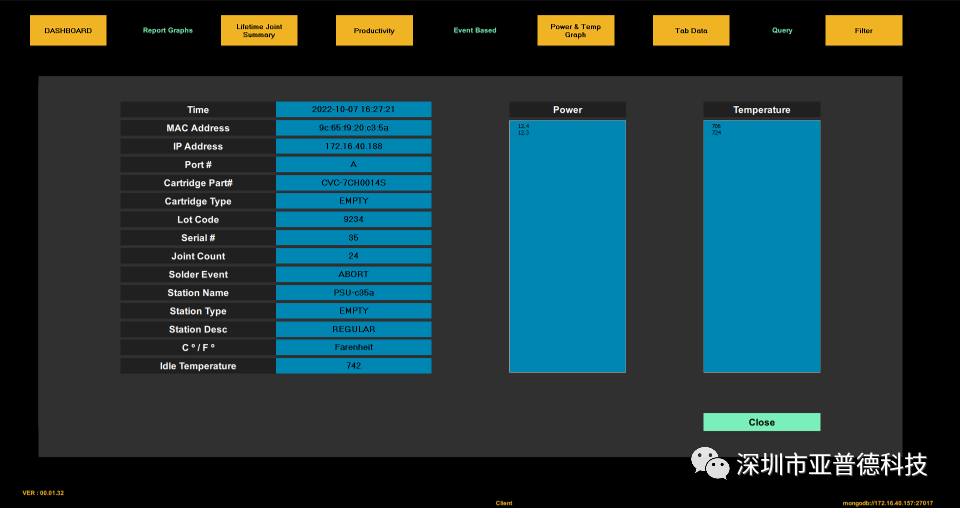

Production managers can view detailed information about each welding station setting and productivity through the welding station information page.

Customize the display effect of the main page using charts with multiple filters, making the information you need easily accessible.

Draw multiple welding events over a period of time to easily visualize productivity and production capacity.

advantage

○ Information about the entire workshop - a clear view of the number of welding stations that have been started and are currently running, as well as the number of welding stations under ESD monitoring;

○Productivity between welding stations - Compare the productivity of welding stations, easily manage production capacity, and check if operators need additional training;

○The lifespan of soldering iron tips is managed by comparing the expected and actual lifespan of the soldering iron tips used on each soldering station to manage costs and productivity.

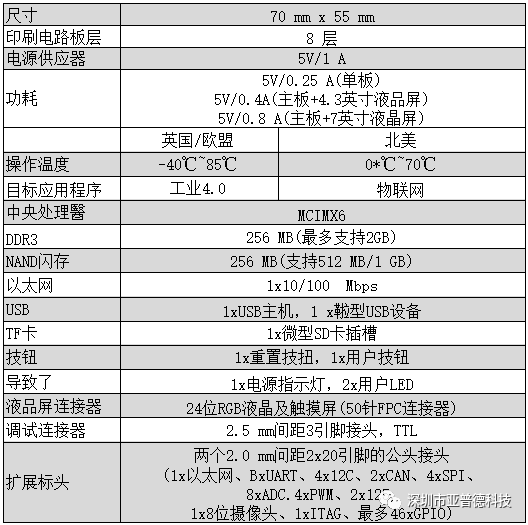

technical specifications

system requirements(including computer hardware)

Welding system requirements

The CV-IOT module and software are compatible with all Connection Verification (CV) welding systems. It is always recommended to upgrade to the latest version of the CV firmware in the system.

Computer hardware requirements

Window 10;

Intel ® CoRE ™ I5 or higher version;

2 GB of memory;

Intel ® Core based graphics card;

At least 150 GB of storage space;

Ethernet 10/100.